Your current location:

Your current location: -

Film/Paper gravure printing

-

Product parameters

Gravure printing water-based ink

Product ingredients:

Luke gravure water-based ink,It is acrylic resin and emulsion,organic pigments and water-based additives composed.

Product features:

environmental protection in line with ROHS international standards.non-toxic,non-flammable, non-explosive, safe and tasteless,low cost,Bright colors,fast drying speed,good scratch resistance,good adhesion,easy operation,does not corrode the printing version.

Product introduction

Applicable machinery: gravure printing machine

Applicable substrate:

1. Kraft paper, white cardboard, coated paper etc paper

2. LDPE, HDPE, BOPP, PET, PVC, PO etc plastic films,breathable film

Gravure ink type:

1, paper gravure printing ink, suitable for paper products.

2, plastic film gravure printing ink: suitable for vest bags, flat pockets, plastic outer packaging, composite packaging etc products printing.

Printing speed: 80~150 m / min.

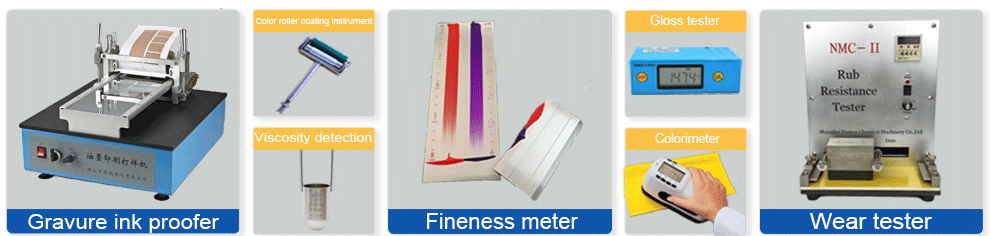

Testing Equipment

Do you want to customize the above products? Please tell me your information?

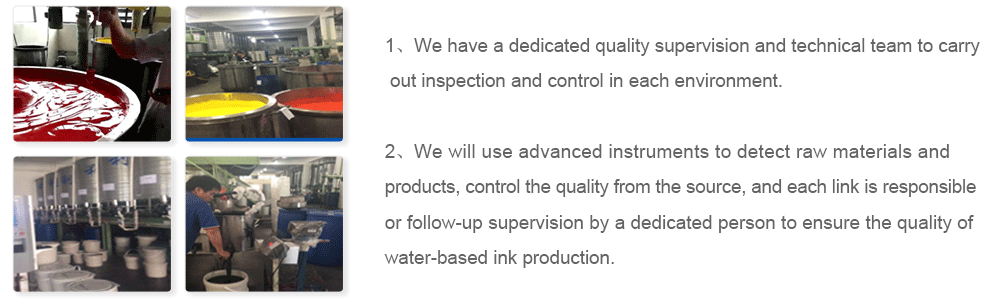

Quality control

The quantity you ordered tells us that we will help you design the loading

quantity of the entire container without wasting space.

Storage method

Per bucket Storage method:

Avoid hihg temperature and sun exposurem,the best storage temperature is 5-35 C. Shelf life under seal is 12 months

Instruction: Mix thoroghly before use, keeping the consistency of water-based ink composition. To prevent dust from

falling and crusting, if the remaining ink contains impurities, filter it first and then use it with new ink. Appropriate amount

of ink before the machine to test the viscosity recommended printing viscosity on the machine 8-12 seconds / coated

4 # cup. This will ensure the ink's adaptability.